Learn more about our foam products

XLPE CROSSLINK

XLPE CROSSLINK

Cross-linked polyethylene (XLPE) or crosslink is a high density closed-foam cell characterized by its compact structure and resistance to water which allows the material to be produced, molded or thermoformed in many ways through compression.

We have a wide variety of XLPE blocks of densities that go from 1.3 lb / ft3 to 15 lb. / ft3. They are available in carbon and grey.

XLPE CHEMICALLY CROSS- LINKED ROLLS

XLPE CHEMICALLY CROSS- LINKED ROLLS

The chemically cross-linked polyethylene (XE) rolls are made of a polyethylene foam that expands in an oven after being extruded with the help of a chemical foaming agent (CFA). The XE roll has a larger cellular structure and a slightly thicker surface in comparison with the irradiated cross-linked polyethylene (XI)

XLPE IRRADIATED SERIES ROLLS

XLPE IRRADIATED SERIES ROLLS

Our rolls of irradiated cross-linked polyethylene (XI) are reticulated through irradiation. With this method the foam acquires a flat surface, uniform density and an even cellular structure with superior physical properties.

It consists of a solution of versatile and lasting foam, as it is resistant to the majority of chemical products and has a low water absorption rate

ZOTEFOAMS AZOTE SERIES

ZOTEFOAMS AZOTE SERIES

Worldwide Foam is proud to announce an agreement with Zotefoams to become its first and only Platinum Distributor in North America. Zotefoams is the world’s leading manufacturer of crosslinked polyethylene block foams. This association allows WF to offer products low in VOC and free of chemicals and that are readily available on the market.

ELASTOMERIC FOAM

ELASTOMERIC FOAM

Worldwide Foam carries a wide offering of elastomeric materials to support complex applications.

Our list of foam products for Original Equipment Manufacturer (OEM) is one of the most diverse in the industry attested to by the number of markets served by our manufacturing customers in North America. The materials we have in storage include neoprene, PVC, nitrile and EPDM.

SEALED AIR

SEALED AIR

Worldwide Foam is the preferred distributor of Sealed Air extruded polyethylene (PE) planks.

In Mexico we currently carry two products in the Sealed Air PE category: ETHAFOAM® and STRATOCELL®.

ETHAFOAM® is a high performance extruded closed cell polyethylene foam. STRATOCELL® is a thermolaminated polyethylene board that delivers high performance strong protection to packaging and non-packaging applications.

PRESSURE SENSITIVE ADHESIVES (PSA)

PRESSURE SENSITIVE ADHESIVES (PSA)

We offer a wide array of pressure sensitive adhesives products (PSA) which adapt to various applications. We can laminate PSA in foam sheets and rolls or we can supply only the adhesive, as the customer requires.

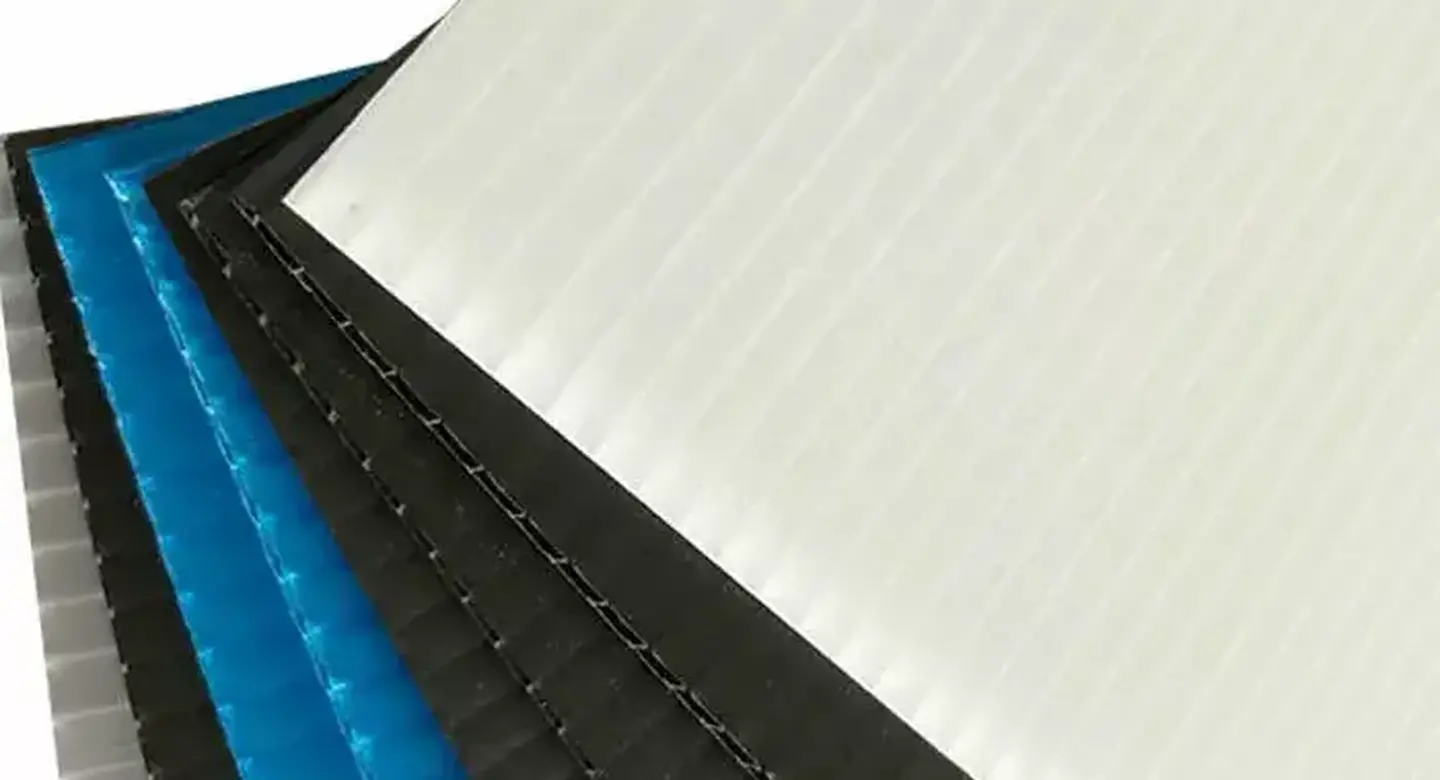

PLASTIC CORRUGATED SHEET

PLASTIC CORRUGATED SHEET

We now carry corrugated plastic sheets in 2, 3, 4 ,5 ,6, and 10mm x 48”x96” C. Blue and black are standard across the board. The 4mm is also available in white.

Our Services

We offer four complementary services that will help the order arrive at your facility ready to use. These services permit the handling and/or transformation of foam rolls or blocks according to each client’s requirements and the increase of efficiency in productive processes.

Heat Lamination

By passing the materials through a heated blade, the heat melts the foam surface, turning it into a sticky substance that basically acts as an adhesive and creates a permanent fusion. It is more cost-effective and has better performance than a glue or adhesive. Various materials, densities and colors can be combined to create multi-layered compound sheets.

Pressure Sensitive Adhesion (PSA)

We offer a wide array of pressure sensitive adhesives (PSA) which adapt to various applications. We can laminate PSA in foam sheets and rolls or we can supply only the adhesive, as the customer requires.

F&K Loopers

Our last generation F&K Loopers can cut through different widths and lengths of rolls, customized to meet client requirements for their equipment and applications. Longer rolls translate into lower costs, faster speeds and higher sales volume per hour of operation.

The F&K Loppers also allow us to turn sheets into continuous rolls by fusing materials using heat or glue.

Dense Foam Cutting (Skiving)

Dense foam cutting (or skiving) functions take place by compacting material between two rolls to then guide it through a fixed ultra-sharp blade. The width is controlled through the relative distance between the rolls and the blade and the level of compression required to direct the foam through the blade. Dividing / beveling with rolls allows for processing large quantities of work faster and the handling of higher-density materials.

We are the supplier with the widest range in polyethylene foam and elastomeric foam.

We are the market leaders in closed-cell polyethylene foam, handling the largest inventory with various densities, whether in rolls or blocks, with unmatched lead time.

We transform the foams for our customers' convenience according to the thickness they require. If needed with pressure-sensitive adhesive, or if they need to heat laminate more than one foam with different characteristics each.

USE ONE OF OUR CALCULATORS:

We have a calculator to measure a roll’s diameter, as well as its density and performance.

Get to know all the resources available:

We have a glossary of support materials that can be downloaded. You can also view all of Worldwide Foam’s certifications.

View Frequently Asked Questions (FAQs)

In this site you can view the answers to our customer’s most frequently asked questions.

Our Commercial Partners