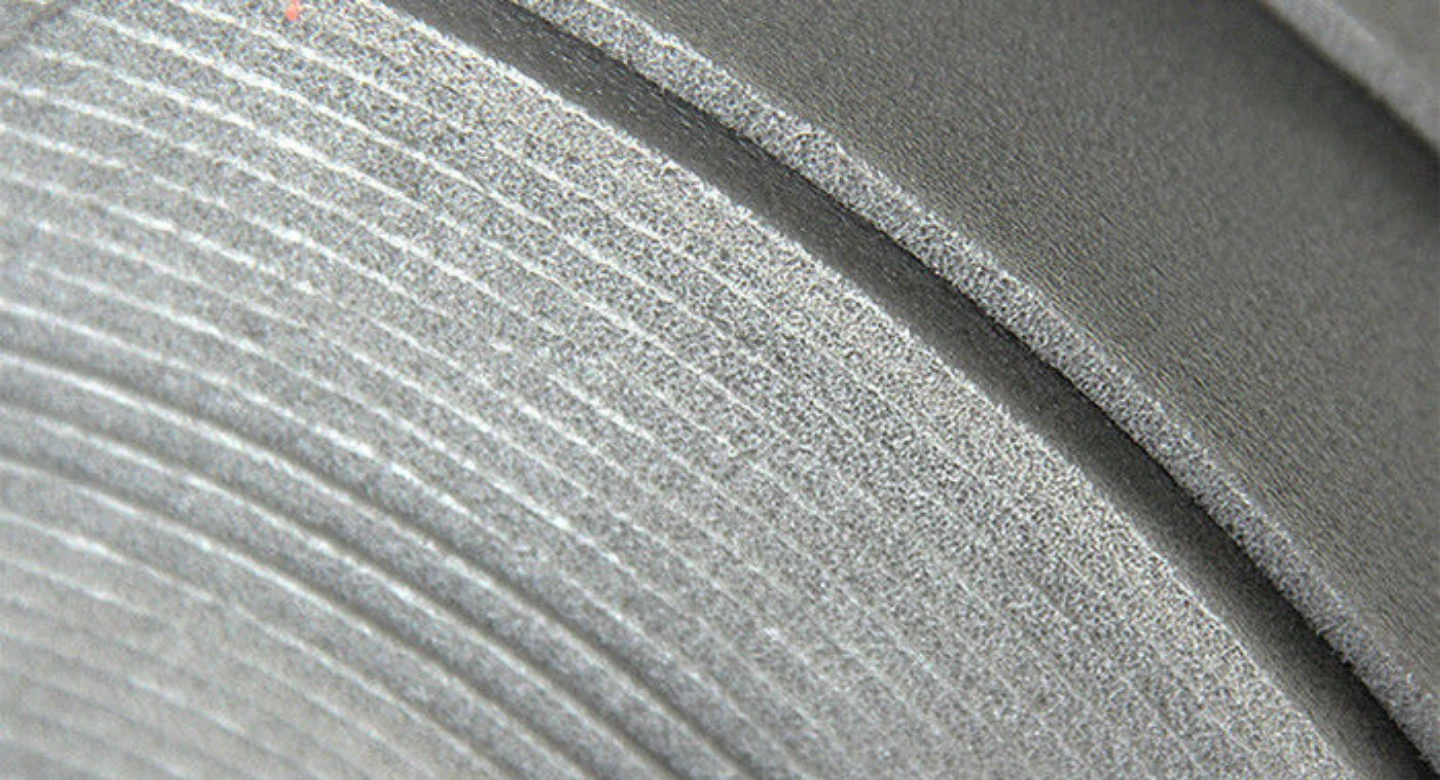

Dense foam cutting (or skiving) functions take place by compacting material between two rolls to then guide it through a fixed ultra-sharp blade. The width is controlled through the relative distance between the rolls and the blade and the level of compression required to direct the foam through the blade. Dividing / beveling with rolls allows for processing large quantities of work faster and the handling of higher-density materials.

Characteristics of the roll cutter:

- Slices through compression

- Faster with higher volumes

- It can handle higher-density foam

Drawbacks and inconveniences:

- Lower precision

- Higher potential variance within a blade and between blades